inherent Vice: optical media

1 CD/DVD Substrate | 2 Data Layers | 3 Reflective Layers | 4 Other Coatings

Optical disc technology was invented in the 1960s and is the basis for the CD and DVD formats that are familiar to us today. In the 1990s, prerecorded compact discs (CDs) became the most popular medium for recorded sound. Various CD formats have since become popular for other applications as well, with CD-ROM (read-only memory) and CD-R (recordable) both introduced in the 1990s for computer applications.

DVD (digital video disc) technology was introduced in 1995 as a medium for playing full-length movies and gradually became dominant over the videotape. There are various formats of DVD, including DVD-ROM for computer data, DVD-RAM (a writeable version of DVD-ROM), and DVD-Audio.

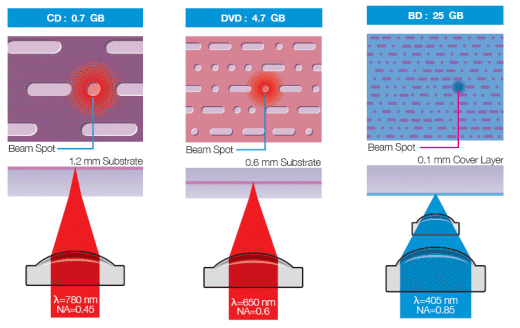

Recently, Blu-ray Disc (BD) format was developed by makers of consumer electronics, computer hardware, and motion pictures to supersede DVD format. The name, Blu-ray, refers to the blue laser used to read the disc which allows information to be stored in higher density than is possible with the longer-wavelength red rays used for DVDs and CDs. Like CDs and DVDs, there are various formats of Blu-ray, including pre-recorded or commercially manufactured BD-ROM, writable BD-R, and rewritable BD-RE.

In addition to the well-known CD, DVD, and Blu-ray formats, dozens of derivative and discontinued optical media formats exist in libraries and archives: MiniDisc, Laserdisc, Super Audio CD, HD DVD and many more.

Structure of Optical Discs

Optical discs are multilayered objects that store digital data; they are used for audio, video, and computer data. To record data onto an optical disc, a laser passes through a polycarbonate support and etches marks (known as pits and lands) into a data layer to represent the bits and bytes of digital data. To read data, the laser passes through the support and the data layer and is reflected off a metal reflective layer (sometimes these are separate layers and sometimes not).

Different types of discs have different structures and composition. A DVD is essentially two CDs glued together; that is, it has two layers of polycarbonate that are joined with adhesive in the center. Thus, CDs can be read and written on one side only, while DVDs can be read and written on one or both sides, depending on the format.

For illustrations of optical disc structure, see Chapter 3 (Disc Structure) of the CLIR report Care and Handling of CDs and DVDs: A Guide for Librarians and Archivists (PDF).

General Stability

When audio CDs first became popular (in the late 1980s and early 1990s), it was thought that optical disc technology would prove to be very stable, but this is not the case. Like other media found in cultural collections, optical media are vulnerable to physical deterioration. In addition, they face the problem of media obsolescence—in many cases the technology to read the media will become obsolete and unavailable before the medium itself deteriorates.

The specific materials that make up the various CD and DVD formats (and their vulnerability to deterioration) will be discussed in this section, as well as the problem of media obsolescence.

1 CD/DVD Substrate

|

|

Both CDs and DVDs have a polycarbonate (clear plastic) substrate (CDs have one layer, while DVDs have two layers joined with adhesive). This stabilizes the disc, keeping it flat, and provides the depth necessary for the laser to focus on the data layer and the metal reflective layer. Thus, in a CD, which is read by the laser from the bottom, the data layer is actually near the top of the disc. In a DVD, the data layers are better protected due to the presence of a polycarbonate layer on both sides of the disc.

Blu-ray Discs, like CDs, have one polycarbonate layer; unlike CDs or DVDs, that layer is on top of the recording layer. To protect that vulnerable and densely packed recording layer, the first Blu-ray Discs were stored in cartridges; now, Blu-ray Discs are protected by a special layer that will be discussed in Other Coatings.

Characteristic Types of Deterioration

Although the polycarbonate will deteriorate over time, the other elements within a disc (e.g., the data layer or the metal reflective layer) will deteriorate more quickly. The polycarbonate layer is vulnerable to poor handling, however. Fingerprints, smudges, scratches, particles of dirt or dust, solvents, or excessive moisture all may interfere with the ability of the laser to read the data layer.

Optical discs are also vulnerable to problems with disc integrity, including separation of the layers, warping, cracking of the layers, and pinholes. These problems are made worse by exposure to high temperature, humidity and extreme fluctuations in climate.

2 Data Layers

The type of data layer(s) used varies according to the format of the disc. Discs can be read-only (ROM), write-once (R), or rewritable many times (RW or RAM).

Read-Only (ROM) Discs

CD-ROM, DVD-ROM, and BD-ROM discs are used for pre-recorded audio, video, and computer applications. In ROM discs, the data layer is not actually separate; it is molded into the polycarbonate substrate and then coated with a metal reflective layer. In CD-ROMs and most DVD-ROMs, this reflective layer is aluminum. However, in order to put more data onto a disc, some DVD-ROMs are double-layered (on one or both sides) and emerging BD-ROMs are multi-layered (up to four layers), meaning that they have multiple metal reflective data layers, most of which are semi-reflective to allow the laser to pass partly through to the next layer. In these types of discs, the semi-reflective layer is made from gold, silver alloy, or silicon.

If moisture or oxygen from the environment penetrates to the inside of the disc, the aluminum can oxidize, making it less reflective and eventually making the disc unreadable (this is known as "disc rot").

Write-Once Discs

These include CD-R, DVD-R, DVD+R, and BD-R discs. In these discs, a separate data layer made up of organic dyes is sandwiched between the polycarbonate substrate and the metal reflective layer. These organic dyes are photosensitive, so marks are made in the data layer via chemical changes caused by the laser beam.

As with all organic dyes, these dyes will deteriorate slowly over time, especially if exposed to high temperatures and humidity. Extensive exposure to ultraviolet (UV) light and/or heat (e.g., sunlight) will also accelerate the deterioration of these dyes. However, if they are well cared for, these discs are much more stable than rewritable discs.

Rewritable Discs

These include CD-RW, DVD-RW, DVD+RW, DVD-RAM, and BD-RE discs. These discs also have a separate data layer sandwiched between the polycarbonate substrate and the metal reflective layer, but this data layer consists of a phase-changing metal alloy film. While this is a complicated process, in essence the laser beam makes marks in this film by heating it and reheating it during the rewriting process.

In rewritable discs, the metal alloy film deteriorates faster than the dyes used in write-once discs, thus making RW and RAM discs less stable. The metal alloy film deteriorates in response to heat, UV light, and high humidity. In addition, the rewriting process affects the life expectancy of rewritable discs; the more times a disc is rewritten, the shorter its life expectancy. Rewritable discs are not intended, and should not be used for long-term or archival storage.

3 Reflective Layers

The reflective layer in an optical disc reflects the laser beam to transmit the data back to the laser head. It is made from different types of metal, depending on the disc format.

Read-Only Discs

These include CD-ROM, DVD-ROM, and BD-ROM discs used for prerecorded audio, video, and computer applications.The data/metal reflective layer is made from aluminum in most of these discs. Aluminum can be subject to oxidation if kept in a humid and hot environment (the polycarbonate substrate will absorb moisture in such a situation, and cracks or scratches will make this worse). In double-layer DVD-ROM discs, there are two data/reflective layers; the first is semi-reflective and made from silicon, gold, or silver alloy, which are much less subject to corrosion.

Write-Once Discs

|

|

These include CD-R, DVD-R, and DVD+R discs. Gold, silver, or silver alloy is used for the metal reflective layer in these discs as well. Silver can corrode by reacting with sulphur dioxide, a pollutant that can migrate through the substrate when it absorbs moisture. Silver alloys are somewhat less vulnerable to this corrosion. Gold is very stable, but it is expensive. All of these metals do not deteriorate as quickly as the dyes used in the data layer, however.

Rewritable Discs

These include CD-RW, DVD-RW, DVD+RW, and DVD-RAM discs. Like read-only discs, these discs use aluminum for the reflective layer, which can be subject to oxidation in poor environmental conditions. However, the metal alloy film used for the data layer will likely deteriorate much more quickly.

4 Other Coatings

Because the data layer is so close to the label side of the disc in a CD, a thin layer of lacquer is usually applied to protect the data layer from exposure to the environment. This is not needed in a DVD, due to the presence of a polycarbonate layer on both sides of the disc. This lacquer layer may protect the CD somewhat from damage due to writing or labeling, but care must still be taken not to damage the coating during handling.

Manufacturers have developed "hard-coating technology" to protect Blu-ray Discs in compliance with the Blu-ray Disc industry specifications requiring the mechanical abrasion tests that prove resistance to scratching. Different manufacturers use different formulations, and only time will tell how stable and effective these coatings are.

Sometimes an extra surface layer is added to an optical disc to provide a surface for labeling, but this also must be treated carefully. The only truly safe surface for labeling is the clear inner hub or the "mirror" band, which do not contain data.